When I talk to my customers, there is a recurring topic that also weighs down employees of documentation departments:

Departments that are already struggling due to a flourishing economy are now having to deal with ever-shorter development times for new products and product variants.

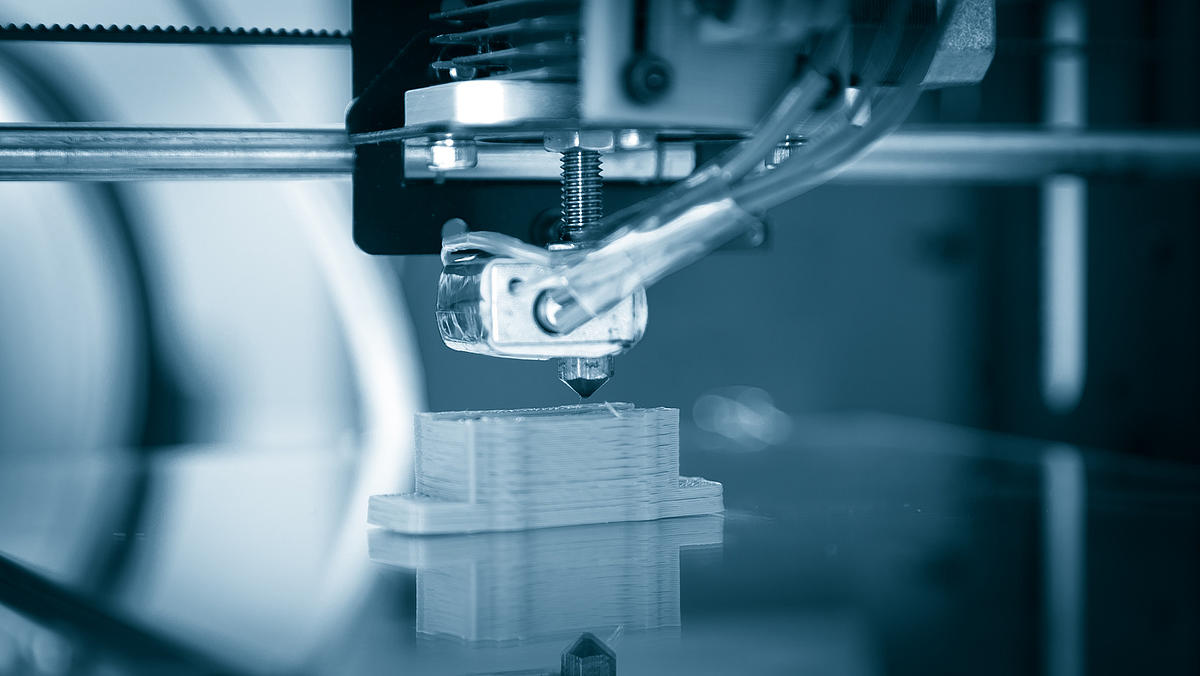

Often, these are achieved through rapid prototyping in development, which involves the use of Additive Manufacturing (AM), also referred to as 3D printing.

Additive manufacturing makes it possible to provide new parts or components within a few hours or days, depending on their complexity. Printing items directly from 3D CAD data often saves a considerable amount of time, because there is no need to build the tools that would traditionally be necessary in injection moulding, for example. The process also allows for greater design freedom, encouraging a tendency to create new variants and making it possible to implement customer-specific solutions.

As technology becomes increasingly industrialised and 3D printers evolve in terms of shorter build times, innovative materials and excellent precision, even small-scale series become possible and profitable. It is not important whether you have a 3D printer in-house, or whether you have to call on the service of an industrial partner.

These shorter development cycles and an abundance of variants generate huge demand for documentation, which is often difficult to meet using existing processes and capacities. This is true for the creation of new documents, their translation, and their subsequent updates and customisations. Not to mention the tedious and time-consuming review and approval processes for many similar contents.

So how can this challenge in technical documentation be met without creating new jobs, which are often difficult to fill and involve permanent additional costs for the area of documentation? That is something that many companies are unwilling to do.

Connecting information intelligently

When working with customers in this position, I often try out a new path that combines new technical options with process optimisations. In the same way that 3D printing has changed processes in development and production, technical documentation has seen the development of processes, methods and tools over recent years that enable efficient and automated processes and partial processes.

A key topic here is the intelligent use of information that has become available through the digitalisation of company processes. Examples include technical data, configuration data, parts lists or 3D data. By connecting this information intelligently, with modular documentation data for example, it is possible to create a smart information solution that can flexibly fulfil a wide range of requirements. Examples include traditional manuals or the effective output of information on mobile systems (e.g. for a service technician).

This additional benefit, which can lead to more efficient processes in other areas and thereby save money, is often the decisive reason for my customers to choose this path.